Scratches and bruises to parts of the body that move around a lot are often the slowest to heal. A scraped knee or a cut near the elbow are tricky places to apply a bandage – and even then, they seldom stay in place for long enough, peeling off as the joint bends even slightly.

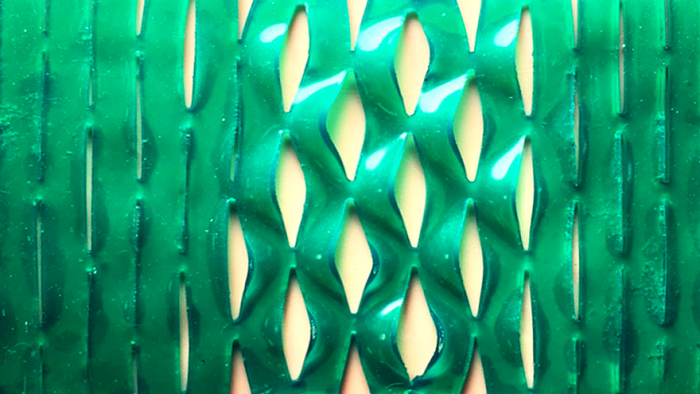

In response to this problem, a group of MIT engineers have come up with a simple structural solution in the form of a thin, rubbery film. It is designed to stick to parts of the body that bend the furthest and maintain its adhesion over time. The key to the new type bandage’s cling-factor is a simple pattern of cuts made in the body of the film which allows it to flex and contract according to the host body part. The pattern is derived from the paper-folding artform known as kirigami.

Coined from the Japanese “kiri” (cut) and “kami” (paper), kirigami involves making intricate and often 3-dimensional sculptures by cutting and folding key sections of a sheet of paper. Referenced for its elegance and ability to transform a plain material into something more complex and 3-dimensional, kirigami has inspired a number of major architectural projects and fashion collections over the years.

Now, it seems kirigami can help us heal too.

“Adhesives like these bandages are very commonly used in our daily life, but when you try to attach them to places that encounter large, inhomogenous bending motion, like elbows and knees, they usually detach,” explains Ruike Zhao, one of the MIT researchers who authored a paper on this kind of design for the journal Soft Matters.

According to Zhao and her colleagues, this straightforward augmentation to the surface of the bandage demonstrates the way forward for other areas of medical design, such as long-term wearable technology. In addition to the rubbery, flexible bandage, the scientists engineered a heat pad threaded with heating wires which can currently maintain a steady heat of 38C to sooth deeper muscle bruises. They also fabricated a wearable electronic film festooned with light-emitting diodes, the first step to creating a version that can record data. All three prototypes proved functional when tested and could cling to the skin well.

“Currently in the soft electronics field, people mostly attach devices to regions with small deformations, but not in areas with large deformations such as joint regions, because they would detach,” Ruike says. “I think kirigami film is one solution to this problem commonly found in adhesives and soft electronics.”

More on medical design innovation:

An impactful project inspired by the designer's own experience recovering in hospital

A sterilisation kit for medical tools has been designed for hospitals in developing countries

Four designers are looking to redesign the gynaecology experience