According to a Quartz article on why upcycling won't change fashion's worst problem, the US delivers an estimated 12.7 million tons of textile waste to landfills a year; China produces a whopping 26 million.

This is on top of the fact that the fashion industry creates about 150 billion pieces of clothing for 7 billion humans each year.

We've decided to focus on what some designers and researchers are doing to try to curb the industry's sustainability crisis before the clothes even it make to the consumer's hands.

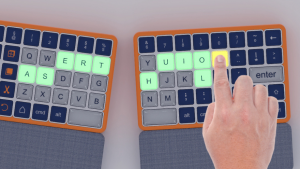

At this year's Design Indaba we hosted a young transdisciplinary design engineer, Kye Shimizu, as part of our Global Graduates programme. He talked about his project, Algorithmic Couture (below), which uses 3D CAD software and algorithms, to create clothes that are more sustainable.

As he explained during his talk: "Using code allows me to create new tools for designers because I feel as designers we are confined to the tools that we use."

Shimizu, a graduate of the Keio University in Japan, says the fashion industry is drowning in waste as they produce too many clothes and sell too little of them. He proposes that instead of the current system where clothes are designed, made and then sold.

How about we first find out who the clothes are being made for, then using digital fabrication we can then make the clothing to fit the consumer and thereby producing less waste in the process.

He adds: "This ensures that we create bespoke garments for everyone, custom-made clothing that matches your body and not some standardised system."

Another former global graduate who works closely with Shimizu is Kazuya Kawasaki. He was also a speaker at the inagural antenna conference that is curated annually by Design Indaba and hosted by the Dutch Design Foundation.

The speculative designer's work aims to bridge the gap between wearable technology and fashion design. What he is proposing is that biohacking fashion can help us create more sustainable garments.

His work, Biological Tailor-made (above) looks at the alternative role of the fashion designer in the age of biotechnology.

To conceptualise a potential future, Kawasaki started a DIY-project in which he combined organisms such as bacteria, yeast, fungi and algae together with liquid in a children’s blow-up pool to produce bacterial cellulose – a material that has similar properties to leather.

The potential for biohacking fashion is something that is also being explored by London-based Natsai Audrey Chieza, founder of Faber Futures.

For the past six years, the Zimbabwean-born design researcher has been working with a bacteria called streptomyces coelicolor.

The bacteria lives in soil where it helps to decompose organic matter. It also produces an antibiotic called actinorhodin, which ranges in colour from blue, pink and purple, depending on the acidity of its environment.

Through a project called Project Coelicolor, Chieza was able to develop a system of design-led microbiology protocols to dye silk scarves into different patterns and colours using this bacteria (above).

While Chieza is figuring out how bacteria can help us dye clothes more sustainably, the 2019 Lexus Design Award winner Lisa Marks is looking at bras. Or more specifically, Marks has created a prototype for an Algorithmic Lace bra (below) designed for people who have had mastectomy surgery.

Marks used advanced 3D modeling to handcraft bespoke bras. The result is both functional and beautiful; a bra that positively impacts the survivor's body aesthetic while also providing fully customised structural comfort.

The design has two advantages: it forgoes the underwire of a typical bra that can cause pain post-surgery and it can create the illusion of symmetry and curves underneath.

She said in an interview with Dezeen: "For women who have had a mastectomy, there is nothing that fits them. They have mastectomy bras that can hold a prosthetic, but there isn't anything they can wear that fits their current shape. This is made to fit their individual body, but it is patterned to give the illusion of symmetry."

More on biodesign and fashion:

Algiknit uses biomaterials to make sneakers with kelp as one of their chosen material